iGulu All-In-One Automated Beer Brewer

As Seen On

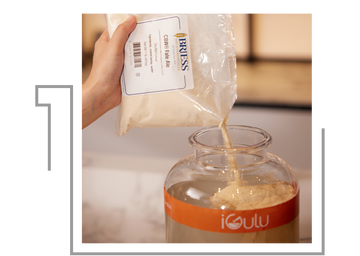

Beer Brewing Ingredient Kits

Each brew kit containing all-natural ingredients that sourced from top global suppliers to enhance beer quality.

Pale Ale represents the craftsmanship of brewing traditions and is cherished by beer lovers worldwide.

Known for its light color and hop-forward flavor profile, is a popular choice among beer enthusiasts.

Bavarian Wheat Beer, also known as Weissbier or Hefeweizen, is renowned for its sweet and fruity flavor. Showcasing a hazy, golden appearance and a creamy texture, it offers prominent flavors of banana and hints of citrus, complemented by a distinct clove aroma.

Amber Lager is a perfectly balanced beer renown for its malty sweetness, hop bitterness, and a toasty, caramel-like flavor profile. With premium extracts and yeast, you'll be assured the brewing process yields a rich, flavorful Amber Lager that's great for any occasion.

Stout is known for its unique blend of ingredients and brewing techniques, resulting in a distinct taste profile. Stout beers often exhibit a balance between malty sweetness and hop bitterness, with hints of citrus or tropical fruit flavors.

Stout Beer Brew Kit (Coming Soon)

Turning a Dream to Reality

Without our supporters and crowdfunding backers, none of this could have been possible, and to that, we say - THANK YOU!

Blog

Company News and Updates

Celebrating the 8 year Journey of iGulu - The Future of Home Brewing

iGulu's journey is a simple, yet profound mission: to bring the art of Craft Beer Brewing into homes around the...

iGulu Unveils the Future of Home Brewing with the F1 Machine, Set to Shine at CES 2024

iGulu, a pioneer in the world of home brewing, is set to showcase its latest innovation, the F1 Machine, at...

iGulu: A Journey of Innovation and Recognition

In the fast-paced world of technology and innovation, a few daring minds with a shared vision can change the game....

MAGELLAN: Where The Company Started

The iGulu team's unwavering passion for beer fuels our continuous exploration and enjoyment of the brewing process. Confronted with the...

HAVE ANY OTHER QUESTIONS?

We're Here to Provide Immediate Support